brass

bike

bell

The project focuses on the materialistic qualities of brass

and spring still, using the technology of metal press.

The dome is made of brass covered with chrome, using the brass's acoustics and its high sustainability in outdoor conditions.

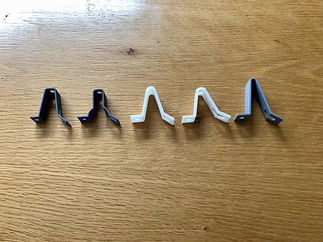

The girth is made of spring steel, using its springiness to strike the dome, and its high sustainability under outdoor circumstances as well.

The bike bell is built from three parts, all produced with the technology of metal press.

This allows a convenient production process “in house”,

by a metal press factory.

The parts are connected to each other by cold connectors

and through their geometry.

Production Steps:

First press:

reinforcement rib

Second press:

cutting out the shape

Third press:

side bendings

Forth press:

upper Bendings

First press:

cutting out the shape

Second press:

bending and cutting off edges

Third press:

reinforcement rib

Process